MK1 Motorsport

1JZ/2JZ Rear Main Seal Installer

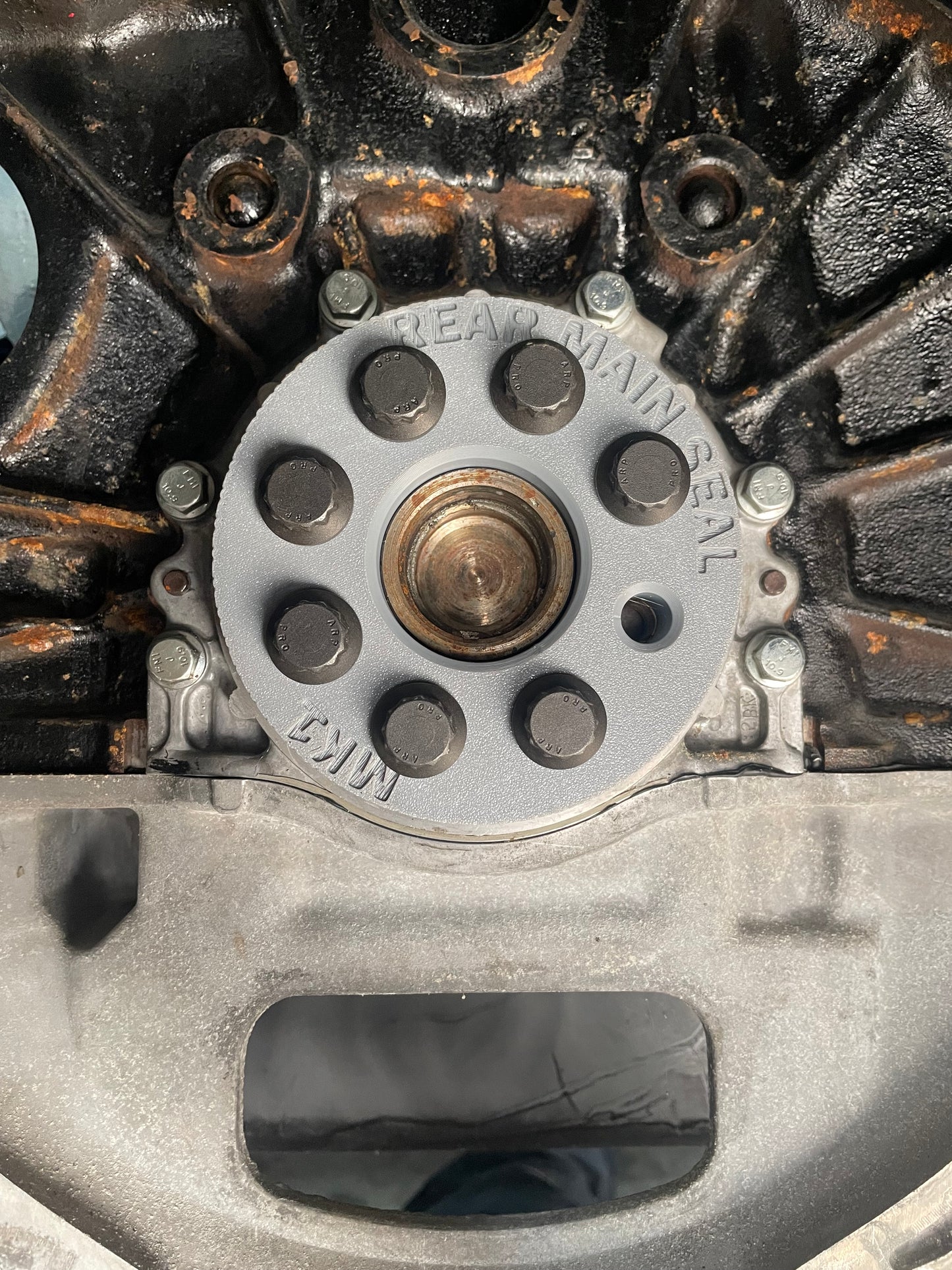

1JZ/2JZ Rear Main Seal Installer

Share

Couldn't load pickup availability

Introducing the FDM printed 1JZ/2JZ Rear Main Seal Installer. Designed for the JZ enthusiast or mechanic to conduct rear main seal service on the JZ engine. As part of regular engine maintenance, this seal must be occasionally replaced. This seal installer tool is a “must” for people who own or regularly work on JZ-powered vehicles.

MK1 understands the absolute nightmare of accessing and maintaining the notoriously leaky front and rear main seals of 1JZ and 2JZ engines. The MK1 Rear Seal Installer is designed to make the hassle of crank seal maintenance a little more bearable. The seal installer component allows you to seat the rear main crank seal in a simple and repeatable manner, after all the hard work required to get to the seal in the first place.

Specifications:

The 1JZ/2JZ Rear Main Seal Installer was manufactured using state-of-the-art FDM printers, as well as a passionate and dedicated engineering team to formulate designs.

This component was printed using high-infill, ASA plastic to prevent part degradation and allow for repeated use. ASA has a high glass transition temperature (GTT) making it ideal for various car components.

All parts are designed and fabricated in the United States.

Application:

The seal installer can be used in two ways.

Method 1 (recommended): Lubricate the inner lip of the seal and place the seal at the location of the rear main seal housing. Place the seal installer over the rear main seal and insert the flywheel bolts into the seal installer. Tighten the bolts until the seal installer bottoms out onto the flywheel end of the crankshaft. Do not over-torque the seal installer (recommended < 14 ft.lbs), a firm fit is all needed.

Method 2: Place the seal onto the rear main seal housing and lightly press it in with the seal installer by hand. Then use a rubber mallet to lightly tap the seal in, until the seal installer bottoms out onto the flywheel end of the crankshaft.

Includes:

- MK1 1JZ/2JZ Rear Main Seal Installer

Note:

Due to the high demand for the part, please allow 1 - 2 weeks of production time.

The product is designed to simulate a flywheel thickness (~19mm). In the case of using a stock flywheel bolt paired with an automatic transmission, or a shortened version of ARP bolts on a twin disk flywheel, we suggest proceeding with the seal installation process with method 2.